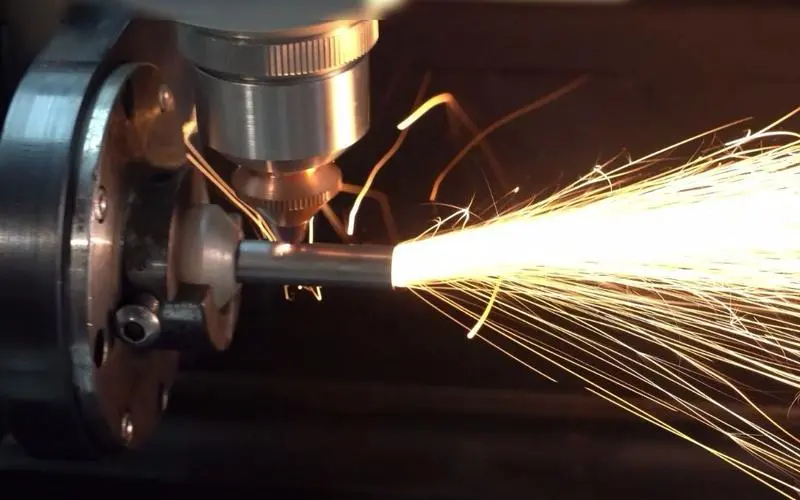

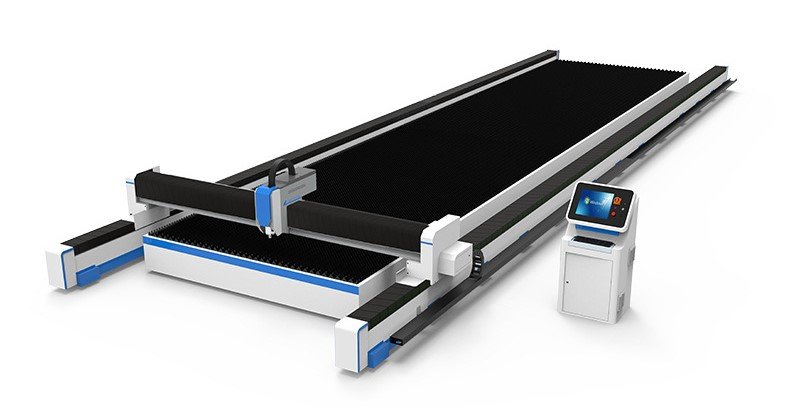

why fiber laser cutting machines are a popular choice for cutting metal sheet?

There are several reasons why fiber laser cutting machines are a popular choice for cutting metal sheets:

Speed: Fiber laser cutting machines are capable of cutting at incredibly fast speeds, which means that they can process large quantities of metal sheet in a short amount of time.

Accuracy: Fiber lasers are incredibly accurate, which means that they can make very precise cuts, even on complex shapes and designs.

Quality: Fiber lasers produce high-quality cuts with smooth edges and minimal burrs, which makes them ideal for applications where a clean finish is important.

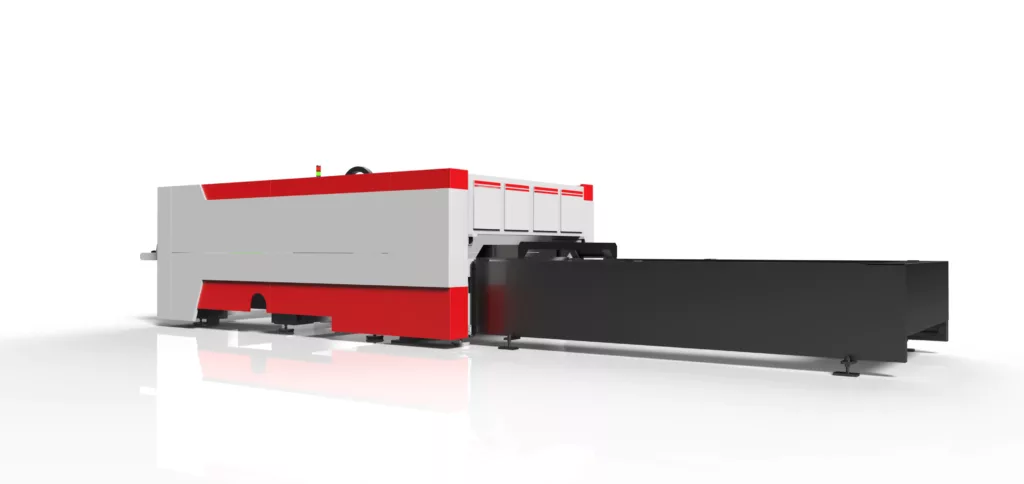

Cost-effective: Although fiber laser cutting machines can be more expensive to purchase initially, they offer a cost-effective solution over the long term due to their low maintenance requirements, high energy efficiency, and low operating costs.

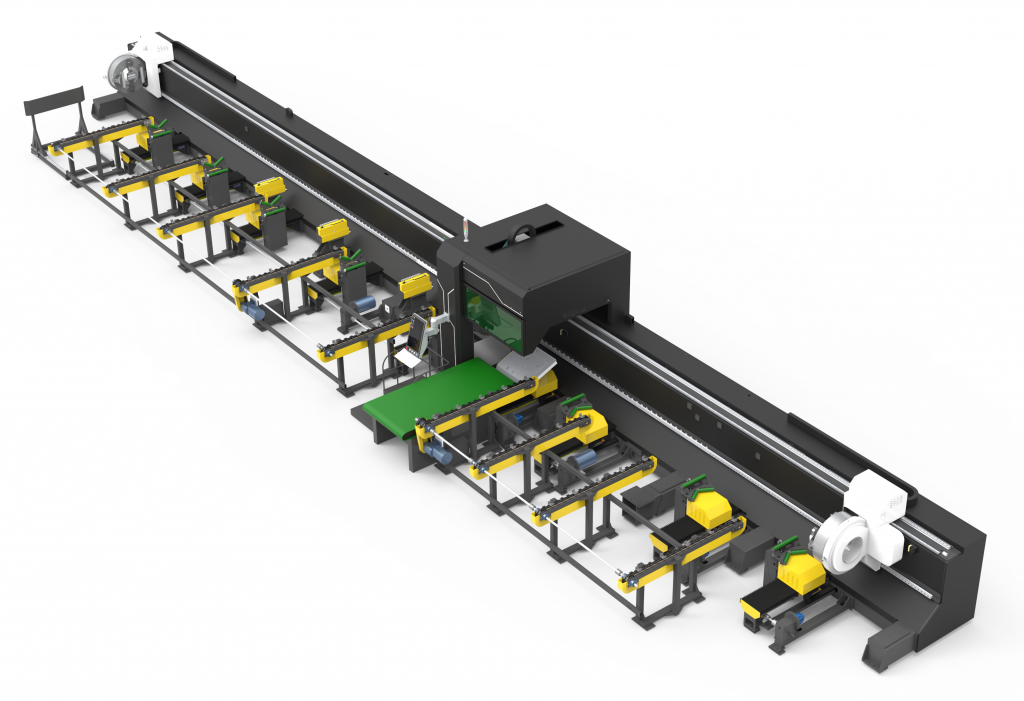

Versatility: Fiber laser cutting machines can be used to cut a wide variety of metals, including steel, aluminum, brass, copper, and more, which makes them a versatile tool for many different industries and applications.

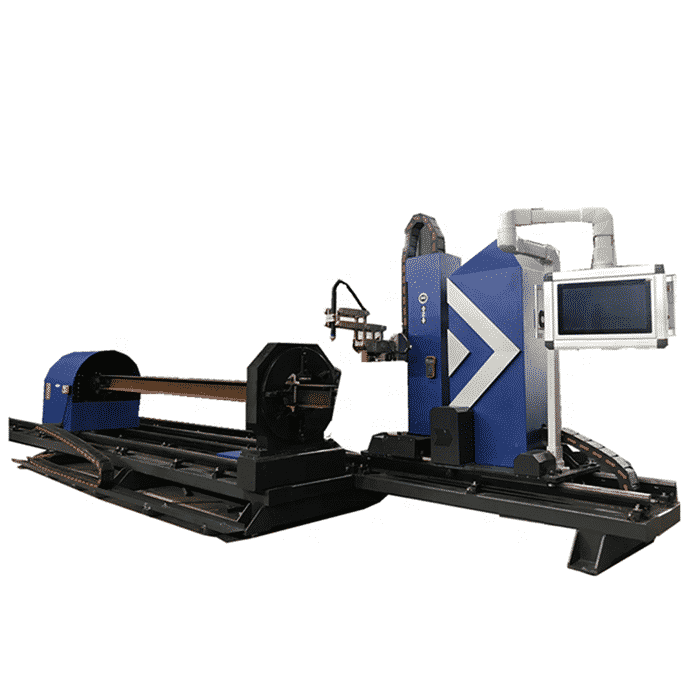

How to choose the metal laser cutting machine

The power of a fiber laser cutting machine required to cut different thicknesses of metal can vary depending on several factors, such as the type of metal, the density of the material, and the desired cutting speed. However, generally speaking, the power of a fiber laser cutting machine required to cut various thicknesses of metal can be summarized as follows:

For cutting thin sheets of metal (up to 3 mm), a laser with a power output of 500w-1000w or less can be used.

For cutting medium-thick sheets of metal (up to 6 mm), a laser with a power output of 1000w-2000 watts is recommended.

For cutting thick sheets of metal (up to 12 mm), a laser with a power output of 2000-3000 watts is required.

For cutting very thick sheets of metal (up to 25 mm), a laser with a power output of 4000w-12000w is necessary.

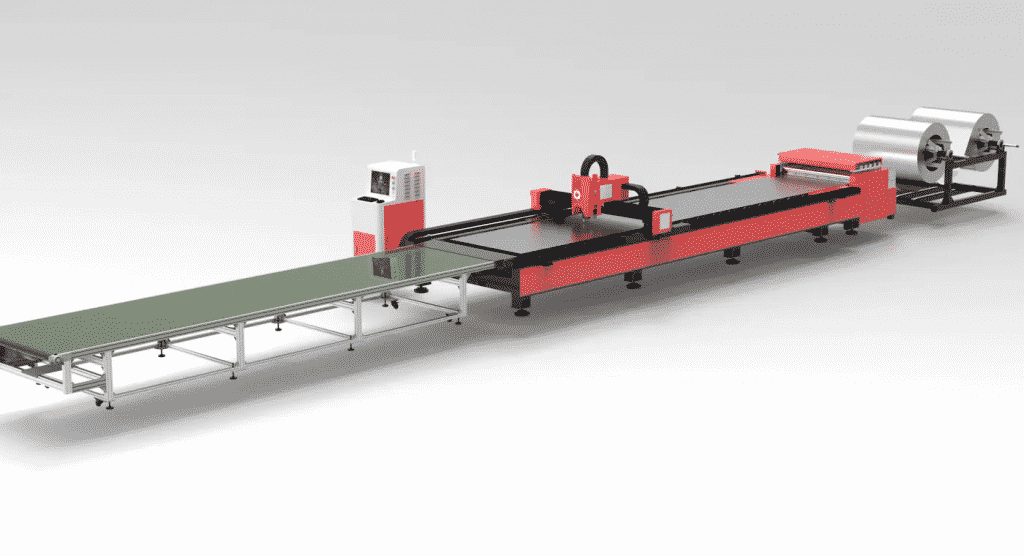

It’s important to note that the power requirement may vary based on the specific type of metal being cut and the desired cutting speed. Additionally, other factors such as the beam quality, cutting head, and assist gas used can also impact the required power output.