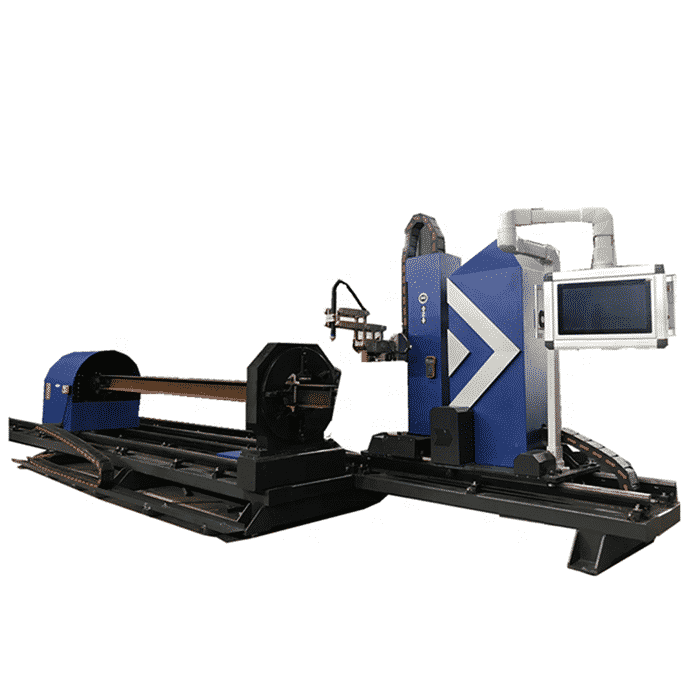

How to cut H beam by plasma cutting machine

The continuity of lines in design for plasma cutting is an important consideration in ensuring the quality and accuracy of the cut. When designing for plasma cutting, it is important to create lines that are continuous and without breaks or gaps. it is same with laser cutting machine, or other cnc machine.

Plasma cutting works by using a high-temperature plasma arc to melt through metal, which is then blown away by a stream of gas. The arc is controlled by a computerized cutting machine that follows a design pattern created using computer-aided design (CAD/solidworks) software. So, you need know how to make design Normatively.

What will happen If Irregular design during plasma cutting H beam.

The cutting work is ugly

If the lines in the design are not continuous, the plasma arc may not be able to follow the path correctly, resulting in a jagged or uneven cut. This can also cause problems with the quality of the cut, as well as slowing down the cutting process and potentially damaging the cutting machine.

To ensure the continuity of lines in design for plasma cutting, it is important to use high-quality CAD software that can create clean and accurate designs. The designs should also be carefully reviewed and checked for any breaks or gaps before they are sent to the cutting machine.

Additionally, it is important to use the right cutting parameters, such as the speed and power of the plasma arc, to ensure that the cut is clean and precise. Regular maintenance of the cutting machine, such as cleaning the nozzle and replacing worn parts, can also help to maintain the quality of the cut and ensure continuity of lines in the design.