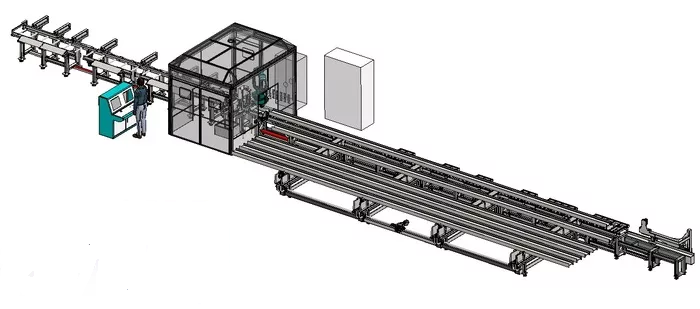

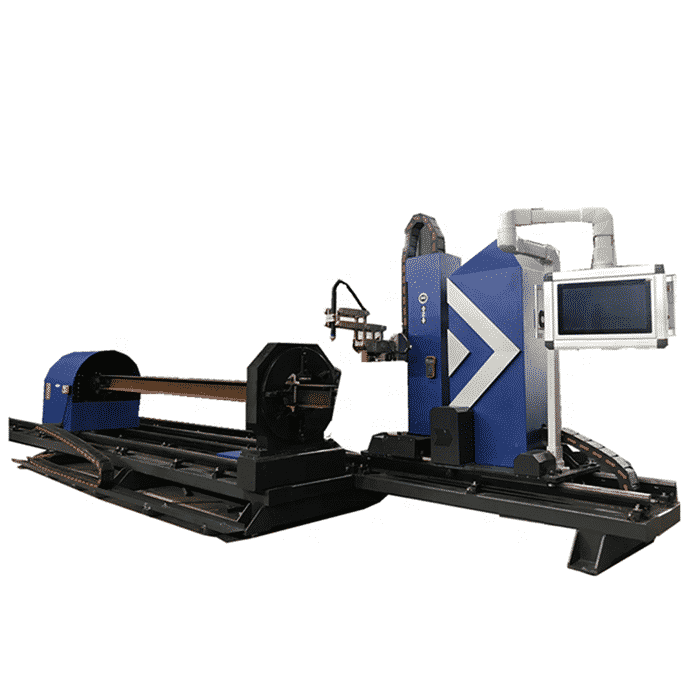

An auto-feeding out system in an H beam cutting machine is a system that automatically removes cut pieces of H beams from the machine’s cutting area and feeds them out of the machine’s working area. The system is typically designed to work with a conveyor belt or roller table that carries the cut pieces away from the cutting area and into a collection area.

The auto-feeding out system typically consists of several components, including sensors, actuators, motors, and controllers. The sensors detect the position and orientation of the cut pieces of H beams, while the motors and actuators control the movement of the conveyor belt or roller table. The controller manages the overall operation of the system and ensures that the cut pieces are removed from the cutting area safely and efficiently.

The benefits of an auto-feeding out system in an H beam cutting machine include increased productivity, improved accuracy, and reduced labor costs. By automating the process of removing cut pieces from the cutting area, the system can operate continuously without the need for human intervention. This allows the machine to cut more H beams in less time and with greater precision, leading to higher output and improved quality.

In summary, an auto-feeding out system is an essential component of an H beam cutting machine that enables the machine to operate more efficiently and effectively.

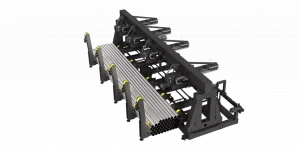

And because client’s cutting work is much different, some client will prefer to build the feeding out system by themself, maybe it is not full auto, but much better and convenient for their work